- Aerospace field

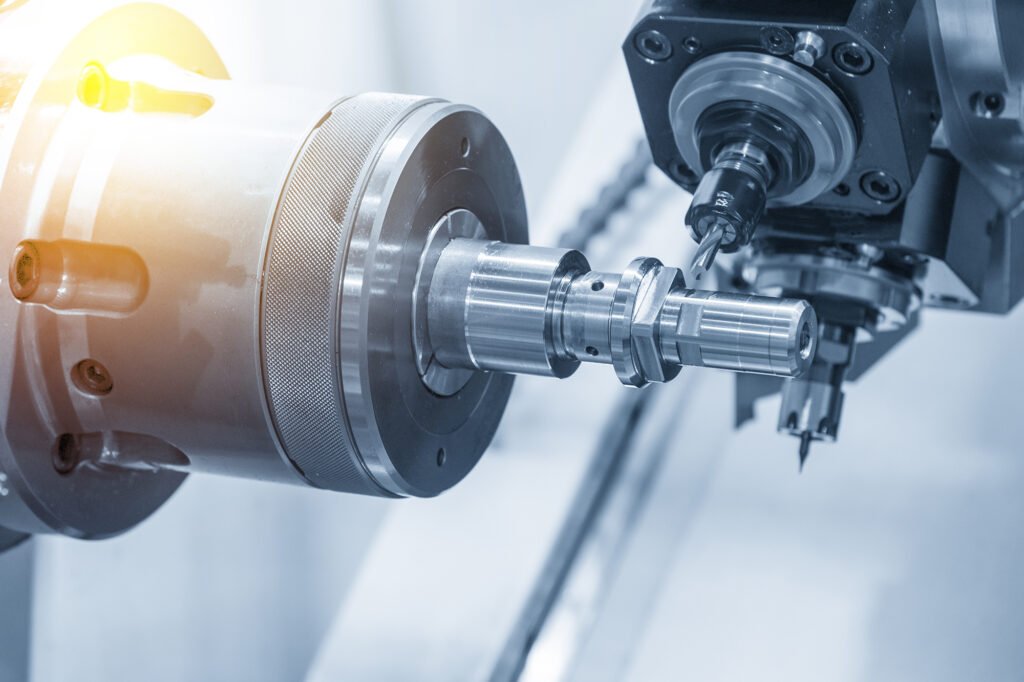

In the aerospace field, the requirements for the precision and quality of components are extremely high. CNC machining can be used to manufacture key components such as aircraft engine blades and turbine discs. These components have complex shapes and require high-precision machining to ensure safe and reliable operation in extreme working environments. For example, the curved shape of engine blades and the complex internal cooling channels can only be precisely achieved through CNC machining. At the same time, aerospace materials usually have characteristics such as high strength and high hardness, and CNC machining equipment can effectively deal with the processing challenges of these materials.

- Automotive manufacturing field

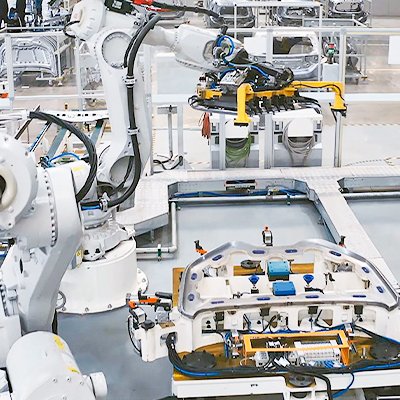

Engine component processing: CNC machining can be used to produce key components of automotive engines such as cylinder blocks, cylinder heads, and crankshafts. The precision of these components directly affects the performance and reliability of the engine. Through CNC machining, high-precision size control and surface quality can be achieved, improving the efficiency and durability of the engine.

Automotive mold manufacturing: The production of automotive shells, interiors and other components requires a large number of molds. CNC machining plays a key role in automotive mold manufacturing and can precisely machine complex mold shapes to ensure that the produced automotive components have high dimensional accuracy and good surface quality.

- Electronic equipment field

Shell processing of electronic products such as mobile phones and computers: These products have high requirements for appearance quality and dimensional accuracy. CNC machining can achieve high-precision cutting, drilling and engraving, and manufacture shells with complex shapes and fine surfaces.

Electronic component manufacturing: In processing links such as drilling and cutting of printed circuit boards (PCBs), CNC machining equipment can complete tasks quickly and accurately, improving production efficiency and quality.

- Medical device field

The manufacturing of medical devices requires a high degree of precision and hygiene standards. CNC machining can be used to produce artificial joints, dental instruments, surgical instruments, etc. For example, the surface accuracy of artificial joints directly affects their adaptability to human bones and service life. CNC machining can ensure the smoothness and dimensional accuracy of the joint surface, improving the treatment effect and quality of life of patients.

- Art and design field

Sculpture production: Artists can use CNC engraving machines to transform their creativity into physical sculpture works. CNC machining can achieve complex shapes and fine details, providing more possibilities for artistic creation.

Jewelry design and manufacturing: CNC machining is widely used in the jewelry industry to produce various exquisite jewelry. It can precisely cut gemstones and engrave metals to create unique and delicate jewelry works.

- Mold manufacturing field

Molds are indispensable tools in industrial production. CNC machining holds an important position in mold manufacturing and can machine molds of various complex shapes, such as injection molds and stamping molds. Through CNC machining, high-precision mold size and surface quality can be achieved, improving the service life and production efficiency of molds.

CNC machining, with its characteristics of high precision, high efficiency and high flexibility, plays an important role in many fields and provides strong support for modern industrial production and innovative design.